| Issue |

A&A

Volume 513, April 2010

|

|

|---|---|---|

| Article Number | A58 | |

| Number of page(s) | 18 | |

| Section | Numerical methods and codes | |

| DOI | https://doi.org/10.1051/0004-6361/200913596 | |

| Published online | 29 April 2010 | |

Numerical simulations of highly porous dust aggregates in the low-velocity collision regime

Implementation and calibration of a

smooth particle hydrodynamics code![[*]](/icons/foot_motif.png)

R. J. Geretshauser1 - R. Speith1 - C. Güttler2 - M. Krause2 - J. Blum2

1 - Institut für Astronomie und Astrophysik, Abteilung Computational

Physics, Eberhard Karls Universität Tübingen, Auf der Morgenstelle 10,

72076 Tübingen, Germany

2 - Institut für Geophysik und extraterrestrische Physik, Technische

Universität zu Braunschweig, Mendelssohnstr. 3, 38106 Braunschweig,

Germany

Received 3 November 2009 / Accepted 22 December 2009

Abstract

Context. A highly favoured mechanism of planetesimal

formation is collisional growth. Single dust grains hit each other with

relative velocities produced by gas flows in the protoplanetary disc.

They stick together with van der Waals forces and form fluffy

aggregates up to a centimetre size. The mechanism responsible for any

additional growth is unclear since the outcome of aggregate collisions

in the relevant velocity and size regime cannot be investigated in the

laboratory under protoplanetary disc conditions. Realistic statistics

for dust aggregate collisions beyond decimetre size are required to

obtain a deeper understanding of planetary growth.

Aims. By combining experimental and numerical

efforts, we wish to calibrate and validate a computer program capable

of accurately simulating the macroscopic behaviour of highly porous

dust aggregates. After testing its numerical limitations thoroughly, we

check the program especially for a realistic reproduction of the

compaction, bouncing, and fragmentation behaviour. This demonstrates

the validity of our code, which will be utilised to simulate dust

aggregate collisions and accurately determine the fragmentation

statistics in future work.

Methods. We adopt the smooth particle hydrodynamics

(SPH) numerical scheme with extensions to the simulation of solid

bodies and a modified version of the Sirono porosity model.

Experimentally measured macroscopic material properties of ![]() dust are implemented. By simulating three different setups, we

calibrate and test for the compressive strength relation (compaction

experiment) and the bulk modulus (bouncing and fragmentation

experiments). Data from experiments and simulations will be compared

directly.

dust are implemented. By simulating three different setups, we

calibrate and test for the compressive strength relation (compaction

experiment) and the bulk modulus (bouncing and fragmentation

experiments). Data from experiments and simulations will be compared

directly.

Results. SPH has already proven to be a suitable

tool for simulating collisions at rather high velocities. In this work,

we demonstrate that its area of application may be beyond low-velocity

experiments and collisions. It can also be used to simulate

the behaviour of highly porous objects in this velocity regime to very

high accuracy. A correct reproduction of density structures in

the compaction experiment, of the coefficient of restitution in the

bouncing experiment, and of the fragment mass distribution in the

fragmentation experiment illustrate the validity and consistency of our

code for the simulation of the elastic and plastic properties of the

simulated dust aggregates. The result of this calibration process is an

SPH code that can be utilised to investigate the collisional

outcome of porous dust in the low-velocity regime.

Key words: hydrodynamics - methods: laboratory - methods: numerical - planets and satellites: formation - protoplanetary disks

1 Introduction

In gaseous circumstellar discs, which are the potential birthplace of planetary systems, dust grains smaller than a micrometre grow to kilometre-sized planetesimals, which themselves proceed to terrestrial planets and cores of giant planets by gravity-driven runaway accretion. Depending on their size, the dust grains and aggregates move relative to each other in the disc. Brownian motion, radial drift, vertical settling, and turbulent mixing cause mutual collisions (Weidenschilling & Cuzzi 1993; Weidenschilling 1977).

Since real protoplanetary dust particles are unavailable for

experiments in the laboratory, much of the following work has

been carried out with dust analogues such as ![]() (Blum & Wurm 2008).

Theoretical models also refer to microscopic and macroscopic properties

of these materials. Initially the dust grains hit and stick on contact

by means of van der Waals forces (Heim

et al. 1999). In this process, which has

been investigated experimentally (Krause & Blum 2004;

Blum

& Wurm 2000; Blum et al. 2000)

and numerically (Paszun & Dominik 2006,2009;

Wada

et al. 2007; Dominik & Tielens 1997;

Wada

et al. 2009,2008; Paszun

& Dominik 2008), they form fluffy aggregates with a

high degree of porosity.

(Blum & Wurm 2008).

Theoretical models also refer to microscopic and macroscopic properties

of these materials. Initially the dust grains hit and stick on contact

by means of van der Waals forces (Heim

et al. 1999). In this process, which has

been investigated experimentally (Krause & Blum 2004;

Blum

& Wurm 2000; Blum et al. 2000)

and numerically (Paszun & Dominik 2006,2009;

Wada

et al. 2007; Dominik & Tielens 1997;

Wada

et al. 2009,2008; Paszun

& Dominik 2008), they form fluffy aggregates with a

high degree of porosity.

Due to restructuring, the aggregates gain a higher mass to

surface ratio and reach higher velocities. Blum & Wurm (2000,2008)

and Wada et al. (2008)

showed that collisions among them lead to fragmentation and mass loss.

Depending on the model of the protoplanetary disc,

which provides the kinetic collision parameters, this means that direct

growth ends at aggregate sizes of a few centimetres. However, Wurm et al. (2005)

and Teiser & Wurm

(2009) demonstrated in laboratory experiments for the

centimetre regime with low-porosity dust that the projectile can stick

partially to the target at velocities higher than 20

![]() .

Thus,

collisional growth beyond centimetre size seems to be possible and the

exact outcome of the fragment distribution is crucial for the

understanding of the growth mechanism.

.

Thus,

collisional growth beyond centimetre size seems to be possible and the

exact outcome of the fragment distribution is crucial for the

understanding of the growth mechanism.

Numerical models that try to combine elaborate protoplanetary disc physics with the dust coagulation problem (Brauer et al. 2008; Weidenschilling et al. 1997; Ormel et al. 2009; Dullemond & Dominik 2005; Zsom & Dullemond 2008; Ormel et al. 2007) have to make assumptions about the outcome of collisions between dusty objects of all sizes and relative velocities. Since data for these collisions are hardly available, in the most basic versions of these models perfect sticking, and in more elaborate ones power-law fragment distributions from experiments and observations (Blum & Münch 1993; Davis & Ryan 1990; Mathis et al. 1977) are assumed. The results of similar simulations depend highly on the assumed fragmentation kernel. However, the given experimental references have been measured only for small aggregate sizes. The influence of initial parameters such as the rotation of the objects or their porosity have not been taken into account for the size regimes beyond centimetre size, although they might play an important role (Sirono 2004; Ormel et al. 2007).

A new approach to modelling the growth of protoplanetary dust aggregates was developed by Güttler et al. (2010) and Zsom et al. (2010), who directly implemented the results of dust aggregation experiments into a Monte Carlo growth model. They found that the bouncing of protoplanetary dust aggregates plays a major role in their evolution as it is able to inhibit further growth and changes their aerodynamic properties. Although their model relies on the most comprehensive database available of dust aggregate properties and their collisional behaviour, they were unable to make direct predictions for any arbitrary set of collision parameters and were thus obliged to perform extrapolations over many orders of magnitude. Some of these extrapolations are based on physical models that need to be supported by additional experiments. Where there is no data available from experiments, the extrapolations have to be supported by sophisticated numerical models such that presented here.

Sticking, bouncing, and fragmentation are the important collision outcomes that need to be implemented into a coagulation code and affect the results of these models. Thus, it is not only important to correctly implement the exact thresholds between these regimes but also details concerning the outcome such as the fragment size distribution, the compaction in bouncing collisions, and maybe even the shape of the aggregates after they have merged in a sticking collision. Due to the lack of important input information, a systematic study of all relevant collision parameters is required and is addressed in this work.

Because of restrictions in size and realistic environment parameters, this task cannot be achieved in the laboratory alone. Much work has been completed on modelling the behaviour of dust aggregates on the basis of molecular interactions between the monomers (Paszun & Dominik 2006,2009; Wada et al. 2007,2009,2008; Paszun & Dominik 2008). However, simulating dust aggregates with a model based on macroscopic material properties such as density, porosity, bulk and shear moduli, and compressive, tensile, and shear strengths remains an open field since these quantities are rarely available. The advantage of this approach over the molecular dynamics method, which is computationally limited to a few ten thousand monomers, is the accessibility of aggregate sizes beyond the centimetre regime.

Jutzi et al. (2008)

implemented a porosity model into the smooth particle hydrodynamics

(SPH) code by Benz & Asphaug

(1994). It was calibrated for pumice material using

high-velocity impact experiments

(Jutzi et al. 2009)

and utilised to understand the formation of an asteroid family (Jutzi 2008). However, pumice is

a material whose strength parameters decrease when it is compacted

(crushed). Additionally, the underlying thermodynamically enhanced

porosity model is designed to describe impacts of some

![]() .

Thus, it is perfectly suitable for simulating

high-velocity collisions of porous rock-like material.

.

Thus, it is perfectly suitable for simulating

high-velocity collisions of porous rock-like material.

In contrast, collisions between pre-planetesimals occur at

relative velocities of some tens of

![]() and compressive, shear, and

tensile strengths increase with increasing

density (Blum

& Schräpler 2004; Güttler et al. 2009; Blum

et al. 2006).

and compressive, shear, and

tensile strengths increase with increasing

density (Blum

& Schräpler 2004; Güttler et al. 2009; Blum

et al. 2006).

Schäfer et al.

(2007) used an SPH code based on the porosity model by Sirono (2004) to simulate

collisions between porous ice in the

![]() regime.

They found that a suitable choice of relations for the material

parameters can produce sticking, bouncing, or fragmentation of the

colliding objects. Therefore, they emphasised the importance of

calibrating the material parameters of porous matter with laboratory

measurements. Numerical molecular-dynamics simulations are

almost capable of using a sufficient number of monomers to be close

enough to the continuum limit and to provide the required material

parameters (e.g., Paszun

& Dominik 2008; reproducing experimental results of Blum & Schräpler 2004).

They represent an important support to the difficult

experimental determination of these quantities. In Güttler et al. (2009),

we measured the compressive strength relation for spherical

regime.

They found that a suitable choice of relations for the material

parameters can produce sticking, bouncing, or fragmentation of the

colliding objects. Therefore, they emphasised the importance of

calibrating the material parameters of porous matter with laboratory

measurements. Numerical molecular-dynamics simulations are

almost capable of using a sufficient number of monomers to be close

enough to the continuum limit and to provide the required material

parameters (e.g., Paszun

& Dominik 2008; reproducing experimental results of Blum & Schräpler 2004).

They represent an important support to the difficult

experimental determination of these quantities. In Güttler et al. (2009),

we measured the compressive strength relation for spherical ![]() dust aggregates for the static case in the laboratory and provided a

prescription of how to apply this to the dynamic case using a

compaction calibration experiment and 2D simulations. We

pointed out relevant benchmark features and demonstrated how the code

is in principal capable of simulating not only fragmentation but also

bouncing, which has not yet been observed in molecular-dynamics codes.

dust aggregates for the static case in the laboratory and provided a

prescription of how to apply this to the dynamic case using a

compaction calibration experiment and 2D simulations. We

pointed out relevant benchmark features and demonstrated how the code

is in principal capable of simulating not only fragmentation but also

bouncing, which has not yet been observed in molecular-dynamics codes.

In this paper, we present our SPH code with its technical details (Sect. 2), experimental reference (Sect. 3), and numerical properties (Sect. 4). On the basis of the compaction calibration simulation, we demonstrate that the results converge for increasing spatial resolution and choose a sufficient numerical resolution (Sect. 4.2). We investigate the differences between 2D and 3D numerical setup (Sect. 4.3) and thereby improve some drawbacks in Güttler et al. (2009). Artificial viscosity is presented as a stabilising tool for various problems in the simulations and its influence on the physical results is highlighted (Sect. 4.4).

Most prominently, we continue the calibration process started in Güttler et al. (2009) utilising two additional calibration experiments for bouncing (Sect. 5.2) and fragmentation (Sect. 5.3). In the end, we possess a collection of material parameters, which is consistent for all benchmark experiments. Finally, the SPH code has gained enough reliability to be used to enhance our information about the underlying physics of dust aggregate collisions beyond the centimetre regime. In future work, it will be applied to generate a catalogue of pre-planetesimal collisions and their outcome regarding all relevant parameters for planet formation. Jointly with experiments and coagulation models, this can be implemented into protoplanetary growth simulations (Güttler et al. 2010; Zsom et al. 2010) to enhance their reliability and predictive power.

2 Physical model and numerical method

2.1 Smooth particle hydrodynamics

The numerical Lagrangian particle method of smooth particle hydrodynamics (SPH) was originally introduced by Lucy (1977) and Gingold & Monaghan (1977) to model compressible hydrodynamic flows in astrophysical applications. The method was later extended (Libersky & Petschek 1990) and improved extensively (e.g., Benz & Asphaug 1994; Randles & Libersky 1996; Libersky et al. 1997,1993) to simulate elastic and plastic deformations of solid materials. A comprehensive description of SPH and its extensions can be found in Monaghan (2005).

In the SPH scheme, continuous solid objects are discretized

into interacting mass packages of so-called ``particles''. These

particles form a natural frame of reference for any deformation and

fragmentation that the solid body may undergo. All spatial field

quantities of the object are

approximated onto the particle positions ![]() by a discretized convolution with a kernel function W.

The kernel W depends on particle

distance

by a discretized convolution with a kernel function W.

The kernel W depends on particle

distance

![]() and

has compact support, determined by the smoothing length h.

We use the standard cubic spline kernel (Monaghan

& Lattanzio 1985) but normalised such that its

maximum extension is equal to one smoothing length h.

and

has compact support, determined by the smoothing length h.

We use the standard cubic spline kernel (Monaghan

& Lattanzio 1985) but normalised such that its

maximum extension is equal to one smoothing length h.

We apply a constant smoothing length. This also allows us to model the fragmentation of solid objects in a simple way. Fragmentation occurs when some SPH particles within the body lose contact with their adjacent particles. Two fragments are completely separated as soon as their respective subsets of particles reach a distance of more than 2 h so that their kernels do not overlap any more.

Time evolution of the SPH particles is computed according to the Lagrangian form of the equations of continuum mechanics, by transferring spatial derivatives by means of partial integration onto the analytically given kernel W.

2.2 Continuum mechanics

A system of three partial differential equations forms the framework of

continuum mechanics. As commonly known they follow from the

constraints of conservation of mass, momentum, and energy.

Accounting for the conservation of mass, the first is called

the continuity equation

Following the usual notation,

|

(2) |

(e.g., Randles & Libersky 1996). Here the sum runs over all interaction partners j of particle i, mj is the particle mass of particle j, and Wij denotes the kernel for the particular interaction. Although this approach is more expensive, as it requires the solution of an additional ordinary differential equation for each particle, it is more stable for high density contrasts and avoids artifacts caused by smoothing at boundaries and interfaces.

The conservation of momentum is ensured by the second equation

|

(3) |

In SPH formulation, the momentum equation reads

|

(4) |

Because of the symmetry in the interaction terms, conservation of momentum is ensured by construction. In addition, we apply the standard SPH artificial viscosity (Monaghan & Gingold 1983). This is essential in particular for stability at interfaces with highly varying densities. The influence of artificial viscosity on our simulation results is investigated thoroughly in Sect. 4.4.

The third equation, the energy equation, is not used in our model.

Hence, we assume that kinetic energy is mainly converted into

deformation energy and energy dissipated by viscous effects is

converted into heat and radiated away. The stress tensor ![]() can be devided into a part representing the pure hydrostatic

pressure p and a traceless part for the

shear stresses, the so-called deviatoric stress

tensor

can be devided into a part representing the pure hydrostatic

pressure p and a traceless part for the

shear stresses, the so-called deviatoric stress

tensor

![]() .

Hence,

.

Hence,

|

(5) |

Any deformation of a solid body leads to a development of internal stresses in a specifically material-dependent manner. The relation between deformation and stresses is not taken into account within the regular equations of fluid dynamics, which are therefore insufficient for describing a perfectly elastic body and have to be extended. The missing relations are the constitutive equations, which depend on the strain tensor

|

(6) |

This represents the local deformation of the body. The primed coordinates denote the positions of the deformed body.

Following Hooke's law a proportional relation between

deformation is assumed involving the material-dependent shear modulus

![]() ,

which depends itself on the density:

,

which depends itself on the density:

However, this is only the constitutive equation for the traceless shear part. For the hydrostatic part of the stress tensor, we adopt a modification of the Murnaghan equation of state, which is part of the Sirono (2004) porosity model:

where

The density dependence of the bulk ![]() and shear

and shear ![]() moduli is modelled by a power law

moduli is modelled by a power law

Although according to Sirono (2004)

The time evolution of the pressure is directly given by the time

evolution of the density (Eq. (1)) and since

the pressure is a scalar quantity it is intrinsically invariant under

rotation. However, to gain a frame-invariant formulation of

the time evolution of the deviatoric stress tensor, i.e., the

stress rate, correction terms have to be added. A very common

formulation for SPH (see e.g., Benz & Asphaug 1994; Schäfer

et al. 2007) is the Jaumann rate form

where

and

To determine rotation rate and strain rate tensor and thus the evolution of the stress tensor Eq. (10) in SPH representation, the SPH velocity derivatives

where the correction tensor

|

(14) |

that is

|

(15) |

This approach leads by construction to first order consistency where the errors caused by particle disorder cancel out and the conservation of angular momentum is ensured. Only this allows rigid rotation to be simulated correctly.

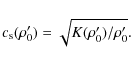

Finally, the sound speed of the material is given by

Together with Eq. (9), this relation shows that the sound speed is a strong function of density. This behaviour has been seen in molecular dynamics simulations by Paszun & Dominik (2008), but there is no data available from laboratory measurements.

Up to this point the set of equations describes a perfectly

elastic solid body. Additionally, the material simulated in this work

are ![]() dust aggregates, which have a high degree of porosity and, thus,

plasticity. The modifications that account for these features are

described in the next section.

dust aggregates, which have a high degree of porosity and, thus,

plasticity. The modifications that account for these features are

described in the next section.

2.3 Porosity and plasticity

Following the Sirono (2004)

model, the porosity ![]() is modelled by the density of the porous material

is modelled by the density of the porous material ![]() and the constant matrix density

and the constant matrix density

![]()

|

(17) |

In the following, we use the filling factor

We model plasticity by reducing inner stresses given

by

![]() .

For this reason, we need constitutive relations describing the

behaviour of the material during plastic deformation. These relations

are specific for each material and have to be determined empirically.

For highly porous materials it is particularly difficult to acquire

them. Therefore, it is advantageous that the model is based on

measurements by Blum &

Schräpler (2004), Blum

et al. (2006), and Güttler

et al. (2009).

.

For this reason, we need constitutive relations describing the

behaviour of the material during plastic deformation. These relations

are specific for each material and have to be determined empirically.

For highly porous materials it is particularly difficult to acquire

them. Therefore, it is advantageous that the model is based on

measurements by Blum &

Schräpler (2004), Blum

et al. (2006), and Güttler

et al. (2009).

The main idea of the adopted plasticity model is to reduce

inner stress once the material

exceeds a certain plasticity criterion. In the elastic case,

described by Eqs. (7)

and (8),

inner stresses grow linearly with deformation. Hence, the material

returns to its original shape at vanishingly external

forces. Reducing inner stresses, i.e., deviating from the

elastic deformation path, reduces the internal ability of the material

to restore its original shape. Therefore, by means of stress

reduction, deformation becomes permanent, i.e., plastic.

Following and expanding the approach by Sirono

(2004), we treat the plasticity of the pure hydrostatic

pressure p and the deviatoric stress

tensor

![]() separately.

separately.

For the deviatoric stress tensor, we follow the approach by Benz & Asphaug (1995) and

Schäfer et al. (2007)

by assuming that our material is isotropic, which makes the

von Mises yield criterion applicable. This criterion is

characterised by the shear strength Y,

which in our model is a composite of the compressive and tensile

strengths

![]() .

The suitability of this choice was already demonstrated in Güttler et al. (2009).

Since

.

The suitability of this choice was already demonstrated in Güttler et al. (2009).

Since ![]() is a scalar, we have to derive a scalar quantity from

is a scalar, we have to derive a scalar quantity from

![]() for reasons of comparability.

We do this by calculating its second irreducible invariant

for reasons of comparability.

We do this by calculating its second irreducible invariant

![]() .

Finally, the reduction of the deviatoric stress is implemented in the

following way

.

Finally, the reduction of the deviatoric stress is implemented in the

following way

|

(18) |

where

For

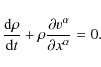

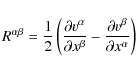

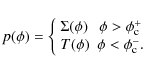

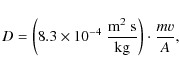

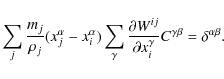

![\begin{figure}

\par\includegraphics[width=8.8cm,clip]{13596f01.eps}

\end{figure}](/articles/aa/full_html/2010/05/aa13596-09/Timg82.png)

|

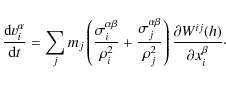

Figure 1:

In the modified Sirono porosity model the regime of elastic deformation

is limited by the compressive strength

|

| Open with DEXTER | |

The pressure reduction process is implemented such that, at each time

step, p is computed using Eq. (8).

If, for a given, ![]()

![]() and

and

![]() ,

then the pressure

,

then the pressure ![]() is reduced to

is reduced to

![]() .

The deformation becomes irreversible once the new reference

density

.

The deformation becomes irreversible once the new reference

density ![]() is computed using Eq. (8) and

the elastic path is shifted towards higher densities. Hereby

the limiting filling factors

is computed using Eq. (8) and

the elastic path is shifted towards higher densities. Hereby

the limiting filling factors

![]() and

and

![]() are also set anew.

In principal, there are two possible

implementations of this: (1) plasticity becomes effective

immediately and

are also set anew.

In principal, there are two possible

implementations of this: (1) plasticity becomes effective

immediately and ![]() is computed whenever

is computed whenever ![]() ;

and (2) plasticity becomes effective after pressure decrease,

which is equivalent to

;

and (2) plasticity becomes effective after pressure decrease,

which is equivalent to

![]() .

We tested both implementations. For our understanding, possibility

(1) is closer to the underlying physical process.

In addition, it has proven to be more stable.

According to the benchmark parameters, the results were equivalent.

.

We tested both implementations. For our understanding, possibility

(1) is closer to the underlying physical process.

In addition, it has proven to be more stable.

According to the benchmark parameters, the results were equivalent.

For the tensile regime, i.e., for

![]() ,

we do not adopt the damage and damage-restoration model presented in Sirono (2004). This damage

model for brittle material such as rocks or pumice was developed for

SPH by Benz

& Asphaug (1994,1995) and used by Jutzi (2008) and Jutzi

et al. (2009,2008). It is assumed

that a material contains flaws, which are activated and develop under

tensile loading (Grady & Kipp

1980). Schäfer

et al. (2007) found that the model is not applicable

to their simulations of porous ice because it includes compressive

damage effects. Brittle material such as pumice and rocks tend to

disintegrate when compressed, i.e., they are crushed.

In contrast in our material of highly porous

,

we do not adopt the damage and damage-restoration model presented in Sirono (2004). This damage

model for brittle material such as rocks or pumice was developed for

SPH by Benz

& Asphaug (1994,1995) and used by Jutzi (2008) and Jutzi

et al. (2009,2008). It is assumed

that a material contains flaws, which are activated and develop under

tensile loading (Grady & Kipp

1980). Schäfer

et al. (2007) found that the model is not applicable

to their simulations of porous ice because it includes compressive

damage effects. Brittle material such as pumice and rocks tend to

disintegrate when compressed, i.e., they are crushed.

In contrast in our material of highly porous ![]() dust, both the tensile and compressive strengths increase with

compression. This is because the monomers are able to form new bonds

when they come into contact. Therefore, we adopt the same approach as

in the

compressive regime and reduce the pressure

dust, both the tensile and compressive strengths increase with

compression. This is because the monomers are able to form new bonds

when they come into contact. Therefore, we adopt the same approach as

in the

compressive regime and reduce the pressure ![]() to

to ![]() once the tensile strength is exceeded. Finally, the material can

rupture because of the plastic flow. However, material that is

plastically stretched can be compressed again up to its full strength.

By choosing this approach, a ``damage restoration

model'' is implemented in a very natural way.

once the tensile strength is exceeded. Finally, the material can

rupture because of the plastic flow. However, material that is

plastically stretched can be compressed again up to its full strength.

By choosing this approach, a ``damage restoration

model'' is implemented in a very natural way.

Finally, a remark has to be made about energy. Apart from

energy dissipation by numerical

and artificial viscosity, we assume intrinsic energy conservation. We

suppose that heat production in the investigated physical processes is

negligible. Therefore, our model is limited to a velocity regime below

the sound speed ![]() of the dust material (

of the dust material (![]() 30 m/s,

see Blum

& Wurm 2008; Paszun & Dominik 2008).

By choosing the approach to modelling plasticity that involves

stress reduction, we assume that most of the energy is dissipated by

plastic deformation, since the reduction in internal stresses accounts

for the reduction in internal energy.

30 m/s,

see Blum

& Wurm 2008; Paszun & Dominik 2008).

By choosing the approach to modelling plasticity that involves

stress reduction, we assume that most of the energy is dissipated by

plastic deformation, since the reduction in internal stresses accounts

for the reduction in internal energy.

Since we do not solve the energy equation thermodynamically enhanced features such as any phase transition such as melting and freezing cannot be simulated. This scheme also does not feature a damage model. When considering fragmentation (Sect. 5.3) in particular, any flaws in the material cannot yet be taken into account, although they might influence the resulting fragment distribution.

3 Experimental reference

3.1 Material parameters

The material used in the calibration experiments are highly-porous dust

aggregates as described by Blum

& Schräpler (2004), consisting of

spherical SiO2 spheres with a diameter

of 1.5 ![]() m.

For these clearly defined dust aggregates, it is possible to

reproducibly measure macroscopic material

parameters such as tensile strength, compressive strength, and,

potentially, also the shear strength needed for the

SPH porosity model (see Sect. 2.3).

The tensile strength of this material was measured for highly porous

and compacted aggregates (

m.

For these clearly defined dust aggregates, it is possible to

reproducibly measure macroscopic material

parameters such as tensile strength, compressive strength, and,

potentially, also the shear strength needed for the

SPH porosity model (see Sect. 2.3).

The tensile strength of this material was measured for highly porous

and compacted aggregates (

![]() )

by Blum & Schräpler (2004).

These measurements support a linear dependence between the tensile

strength and the number of contacts per monomer (increasing with

increasing

)

by Blum & Schräpler (2004).

These measurements support a linear dependence between the tensile

strength and the number of contacts per monomer (increasing with

increasing ![]() ),

which yields the tensile strength as

),

which yields the tensile strength as

The compressive strength was measured in the experimental counterpart of this paper (Güttler et al. 2009) with an experimental setup to determine the static omni-directional compression (ODC), whereby the sample is enclosed from all sides and the pressure is constant within the sample. We found that the compressive strength curve can be well described by the analytic function

where the free parameters were measured to be

3.2 Calibration experiment

As a setup for an easy and well-defined calibration experiment (see Güttler et al. 2009), we chose a glass bead with a diameter of 1 to 3 mm, which impacts into the dust aggregate material with a velocity of between 0.1 and 1 m s-1 under vacuum conditions (pressure 0.1 mbar). We were able to measure the deceleration curve, stopping time, and intrusion depth of the glass bead (for various velocities and projectile diameters) and the compaction of the dust under the glass bead (for a 1.1 mm projectile with a velocity of 0.65 m s-1). These results help us to calibrate and test the SPH code.

For the measurement of the deceleration curve, we used an

elongated epoxy projectile instead of the glass bead. The bottom shape

and the mass resembled the glass bead, while the lower density and the

therefore longer extension made it possible to observe the projectile

during the intrusion. The projectile was observed by a high-speed

camera (12 000 frames per second) and the position of

the upper edge was followed with an accuracy of

![]() m.

We found

that - independently of velocity and projectile

diameter - the intrusion curve can be described by a sine

curve

m.

We found

that - independently of velocity and projectile

diameter - the intrusion curve can be described by a sine

curve

where, D and

For the intrusion depth, we found good agreement with a linear

behaviour of

where v is the impact velocity of the projectile and m and

The compaction of dust underneath the impacted glass bead was

measured by X-ray micro-tomography. The glass bead diameter and

velocity in these experiments corresponded to the compaction

calibration setup described in Table 1.

The dust sample with an embedded glass bead was positioned onto a

rotatable sample carrier between an X-ray source and the detector.

During the rotation through

![]() ,

400 transmission images were taken, from which we computed

a 3D density reconstruction with a spatial resolution

of 21

,

400 transmission images were taken, from which we computed

a 3D density reconstruction with a spatial resolution

of 21 ![]() m.

The corresponding results for the density reconstruction can be found

in Güttler et al. (2009),

where we found that roughly one sphere volume beneath the glass bead is

compressed to a volume-filling factor of

m.

The corresponding results for the density reconstruction can be found

in Güttler et al. (2009),

where we found that roughly one sphere volume beneath the glass bead is

compressed to a volume-filling factor of

![]() ,

while the surrounding volume is nearly unaffected with an original

volume-filling factor of

,

while the surrounding volume is nearly unaffected with an original

volume-filling factor of

![]() .

In this work, we focus on the vertical density profile through

the centre of the sphere and the compressed material

(see Sect. 4).

.

In this work, we focus on the vertical density profile through

the centre of the sphere and the compressed material

(see Sect. 4).

Table 1: Numerical parameters for the compaction calibration setup.

3.3 Additionaly benchmark experiments

We present two additional experiments used to validate the

SPH code in Sects. 5.2

and 5.3.

Heißelmann et al.

(2007) performed low-velocity collisions (v=0.4 m s-1)

between cubic-shaped, approximately 5 mm-sized aggregates of

the

material as described in Sect. 3.1

and found bouncing whereby about 95% of the energy was

dissipated in a central collision. Detailed investigation of the

compaction in these collisions (Weidling

et al. 2009) revealed significant compaction of the

aggregates

(from ![]() to

to ![]() )

after approximately 1000 collisions. The energy needed for

this compaction is consistent with the energy dissipation measured by Heißelmann et al.

(2007).

)

after approximately 1000 collisions. The energy needed for

this compaction is consistent with the energy dissipation measured by Heißelmann et al.

(2007).

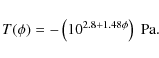

![\begin{figure}

\par\includegraphics[angle=90,width=8.5cm,clip]{13596f02.eps}

\end{figure}](/articles/aa/full_html/2010/05/aa13596-09/Timg126.png)

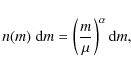

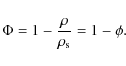

|

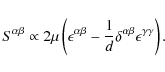

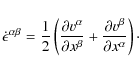

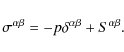

Figure 2: Cumulative mass distribution of the fragments after a disruptive collision, which can be described by a power law. The divergence at low masses is caused by the depletion of small aggregates because of the camera resolution. |

| Open with DEXTER | |

An additional experiment deals with the disruptive fragmentation of

dust aggregates

(for details, see Güttler et al. 2010,2009).

In this case, a dust aggregate with a diameter of

0.57 mm consisting of 1.5 ![]() m spherical SiO2

dust with a volume-filling factor of

m spherical SiO2

dust with a volume-filling factor of ![]() collides with a

solid glass target at a velocity of 8.4 m s-1

(also see Fig. 20

in Güttler et al. 2009).

The projectile fragments and the projected sizes of these fragments are

measured with a high-speed camera with a resolution of 16

collides with a

solid glass target at a velocity of 8.4 m s-1

(also see Fig. 20

in Güttler et al. 2009).

The projectile fragments and the projected sizes of these fragments are

measured with a high-speed camera with a resolution of 16 ![]() m per pixel.

As the mass measurement is restricted to the

2D images, the projected area of each fragment is

averaged over a sequence of images, where it is clearly separated from

other fragments. From this projected area, the fragment masses

are calculated with the assumptions of a spherical shape and an

unchanged volume filling factor. Figure 2 shows

the mass distribution in a cumulative plot. For higher masses,

which are not depleted by the finite camera resolution, we find good

agreement with a power-law distribution

m per pixel.

As the mass measurement is restricted to the

2D images, the projected area of each fragment is

averaged over a sequence of images, where it is clearly separated from

other fragments. From this projected area, the fragment masses

are calculated with the assumptions of a spherical shape and an

unchanged volume filling factor. Figure 2 shows

the mass distribution in a cumulative plot. For higher masses,

which are not depleted by the finite camera resolution, we find good

agreement with a power-law distribution

where m is the normalised mass (fragment mass divided by projectile mass) and

4 Numerical issues

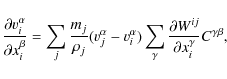

Before we perform the calibration process, some numerical issues have to be resolved. For instance, it is unfeasible to simulate the dust sample, into which the glass bead drops in the compaction calibration experiment presented in Sect. 3, as a whole. It is also infeasible to carry out all necessary computations in 3D. Therefore, we simulate only part of the dust sample and attempt to determine the size at which spurious boundary effects emerge. Most of the calibration process was conducted in 2D, but the differences between 2D and 3D results are discussed and quantified.

In this context, we use the results of 2D simulations in cartesian coordinates, although the symmetry of the problem would be more accurately described by cylindrical coordinates. However, the SPH scheme in cylindrical or polar coordinates battles with the problem of a singularity at the origin of the kernel function. There have been only a few attempts to resolve this issue (e.g., Omang et al. 2006), which, however remain under development and require high implementation efforts. In our case, since 2D simulations provide only an indication of the calibration required and 3D simulations are aimed at, we stick to cartesian coordinates.

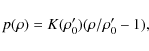

The glass bead is simulated with the Murnaghan equation

of state

![\begin{displaymath}%

p(\rho) = \left( \frac{K_0}{n} \right)

\left[ \left( \frac{\rho}{\rho_0} \right)^n - 1 \right],

\end{displaymath}](/articles/aa/full_html/2010/05/aa13596-09/img130.png)

|

(25) |

following the usual laws of continuum mechanics as presented in Sect. 2.2. The compaction calibration setup is initialised with the numerical parameters shown in Table 1, unless stated otherwise in the text. Our tests showed that the maximum intrusion depth and the density profile are the calibration parameters most sensitive to changes in the numerical setup. Density profiles (e.g., Figs. 4 and 5) display the filling factor

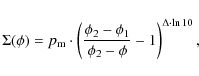

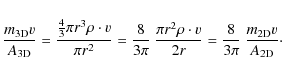

![\begin{figure}

\par\includegraphics[width=6cm,clip]{13596f03.eps}

\end{figure}](/articles/aa/full_html/2010/05/aa13596-09/Timg131.png)

|

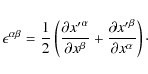

Figure 3:

Compaction calibration setup in 2D or, respectively,

cross-section of 3D compaction calibration setup.

A glass sphere impacts into a dust sample (radius

|

| Open with DEXTER | |

4.1 Computational domain and boundary conditions

In 2D simulations, we tested the effect of changing the size and shape

of the dust sample. Initially the particles were set on a triangular

lattice with a lattice constant of 25 ![]() .

To be geometrically consistent with the cylindric experimental

setup, we firstly utilised a box (width 8 mm) and

varied its depth: 1.375 mm, 2.2 mm, 3.3 mm,

and 5.5 mm. This is equivalent to the dimensions

.

To be geometrically consistent with the cylindric experimental

setup, we firstly utilised a box (width 8 mm) and

varied its depth: 1.375 mm, 2.2 mm, 3.3 mm,

and 5.5 mm. This is equivalent to the dimensions

![]() ,

,

![]() ,

,

![]() ,

and 10

,

and 10 ![]()

![]() .

Comparing the density profiles (Fig. 4,

top), two features are remarkable: (1) the maximum filling

factor at the top of the dust sample (

.

Comparing the density profiles (Fig. 4,

top), two features are remarkable: (1) the maximum filling

factor at the top of the dust sample (

![]() at

at

![]() )

and the intrusion depth D is nearly the

same for all dust sample sizes. (2) For

)

and the intrusion depth D is nearly the

same for all dust sample sizes. (2) For

![]() ,

we find spurious density peaks at the lower boundaries (

,

we find spurious density peaks at the lower boundaries (

![]() and

and

![]() ).

).

To reduce the computation time, we simulated the dust sample

as a semicircle with the same radius variation as above. The resulting

density profiles are shown in Fig. 4

(bottom). In contrast to the corresponding simulations with

the box-shaped samples, we find for

![]() an increased maximum filling factor and a slightly reduced intrusion

depth. Because of the greater amount of volume lateral to the

intrusion channel, material can be pushed aside more easily than inside

the narrow boundaries of the semicircle. Therefore, a higher

fraction of the material is compressed to higher filling factors.

For

an increased maximum filling factor and a slightly reduced intrusion

depth. Because of the greater amount of volume lateral to the

intrusion channel, material can be pushed aside more easily than inside

the narrow boundaries of the semicircle. Therefore, a higher

fraction of the material is compressed to higher filling factors.

For

![]() ,

the spurious boundary effects become negligible within the compaction

calibration setup and the density structure shows no significant

difference for box-shaped and semicircle-shaped dust samples.

,

the spurious boundary effects become negligible within the compaction

calibration setup and the density structure shows no significant

difference for box-shaped and semicircle-shaped dust samples.

Hence, all computations of Sect. 4 are

conducted on the basis of a semicircle in 2D or a hemisphere

in 3D with a radius of

![]() .

.

In all cases, the dust sample is bordered by a few layers of

boundary particles. The acceleration of these particles is set to zero

at each integration step, simulating reflecting boundary conditions.

Apart from that, i.e., in terms of the equation of

state, they are treated like dust particles. We also tested damping

boundary conditions by simulating two layers of boundaries. The outer

layer was treated as described above, the inner (sufficiently large)

layer was simulated with a high artificial ![]() -viscosity. Since there was no

significant difference in the outcome, we fix all boundaries

in the aforementioned way and consider them to be reflecting.

-viscosity. Since there was no

significant difference in the outcome, we fix all boundaries

in the aforementioned way and consider them to be reflecting.

![\begin{figure}

\par\includegraphics[angle=-90,width=8cm,clip]{13596f04.ps}\vspace*{3mm}

\includegraphics[angle=-90,width=8cm,clip]{13596f05.ps}

\end{figure}](/articles/aa/full_html/2010/05/aa13596-09/Timg146.png)

|

Figure 4:

Vertical density profile at maximum intrusion for the compaction

calibration setup and different shapes of the 2D dust sample

(box and semicircle).

Depth

|

| Open with DEXTER | |

4.2 Resolution and Convergence

Jutzi (2008) found in his studies of a basalt sphere impacting a porous target that the outcome of his simulations strongly depended on their resolutions. With a calibration setup similar to that used in this paper, Geretshauser (2006) confirms that in simulations of the type presented in this work, a strong resolution dependence is present. He found that the intrusion depth of the glass bead can be doubled by doubling the resolution. Since the calibration experiments presented in Güttler et al. (2009) are extremely sensitive even to minor changes in the setup, the convergence properties of porosity model and the underlying SPH method are investigated carefully in this paragraph. Additionally, we study the differences in the outcome of 2D and 3D setup.

For the 2D convergence study, particles were initially placed

on a triangular lattice again. The lattice constants ![]() were 100, 50, 25, and 12.5

were 100, 50, 25, and 12.5 ![]() for the compaction calibration setup. The smoothing length h

was kept constant relative to

for the compaction calibration setup. The smoothing length h

was kept constant relative to ![]() at a ratio of 5.6

at a ratio of 5.6 ![]()

![]() .

The maximum number of interaction partners was

.

The maximum number of interaction partners was

![]() ,

the average

,

the average

![]() ,

and the minimum

,

and the minimum ![]() .

.

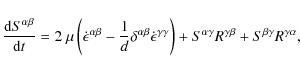

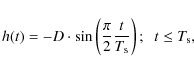

![\begin{figure}

\par\includegraphics[angle=-90,width=8cm,clip]{13596f06.ps}\vspace*{3mm}

\includegraphics[angle=-90,width=8cm,clip]{13596f07.ps}

\end{figure}](/articles/aa/full_html/2010/05/aa13596-09/Timg151.png)

|

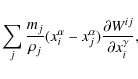

Figure 5: Convergence study of the vertical density profile for 2D ( top) and 3D ( bottom) compaction calibration setups. The increase in filling factor towards the surface of the dust sample accounts for the glass bead, which is not removed in this plot. Simulations were performed for different spatial resolutions. All curves show a characteristic filling-factor minimum between the sphere and dust sample and a characteristic filling-factor maximum indicating the dust sample surface. |

| Open with DEXTER | |

In the 3D convergence study, we used a cubic lattice with edge lengths ![]() =

100, 50, and 25

=

100, 50, and 25 ![]() .

The latter was simulated with 3.7 million

SPH particles, which represent the limit of our computational

resources. We fixed h = 3.75

.

The latter was simulated with 3.7 million

SPH particles, which represent the limit of our computational

resources. We fixed h = 3.75 ![]()

![]() ,

which yielded

,

which yielded ![]() ,

,

![]() ,

and

,

and ![]() .

The results are presented in Fig. 5.

In contrast to the plots in Fig. 4,

the glass sphere is not removed here. Coming from the right side of the

plot, the filling factor rapidly decreases from a high value beyond the

edge of the plot describing the sphere. The filling factor reaches its

minimum at an artificial gap between sphere and surface of the dust

sample.

The width of this gap is about one smoothing length h.

The existence of the gap has two reasons: (1) sphere material

and dust material have to be separated by artificial viscosity for

stability reasons. This is discussed below. (2) The volume of

the sphere represents an area of extremely high density and pressure

with respect to the dust sample. This area is smoothed out by the

SPH method, the width of the smoothing being given by the

smoothing length. Although clear convergence behaviour is evident in

Fig. 5

for both the 2D and the 3D case, a more unique

convergence criterion has to be found. For this purpose, we

choose the maximum intrusion depth, which proved to be very sensitive

to resolution changes. The shape of the filling-factor profile provides

two ways to determine the intrusion depth: (1) the filling

factor minimum, which is inbetween sphere and dust sample; and

(2) the filling factor maximum (peak) of the dust material

left in the gap between sphere and dust sample.

.

The results are presented in Fig. 5.

In contrast to the plots in Fig. 4,

the glass sphere is not removed here. Coming from the right side of the

plot, the filling factor rapidly decreases from a high value beyond the

edge of the plot describing the sphere. The filling factor reaches its

minimum at an artificial gap between sphere and surface of the dust

sample.

The width of this gap is about one smoothing length h.

The existence of the gap has two reasons: (1) sphere material

and dust material have to be separated by artificial viscosity for

stability reasons. This is discussed below. (2) The volume of

the sphere represents an area of extremely high density and pressure

with respect to the dust sample. This area is smoothed out by the

SPH method, the width of the smoothing being given by the

smoothing length. Although clear convergence behaviour is evident in

Fig. 5

for both the 2D and the 3D case, a more unique

convergence criterion has to be found. For this purpose, we

choose the maximum intrusion depth, which proved to be very sensitive

to resolution changes. The shape of the filling-factor profile provides

two ways to determine the intrusion depth: (1) the filling

factor minimum, which is inbetween sphere and dust sample; and

(2) the filling factor maximum (peak) of the dust material

left in the gap between sphere and dust sample.

![\begin{figure}

\par\includegraphics[angle=-90,width=8cm,clip]{13596f08.ps}\vspace*{2mm}

\includegraphics[angle=-90,width=8cm,clip]{13596f09.ps}

\end{figure}](/articles/aa/full_html/2010/05/aa13596-09/Timg157.png)

|

Figure 6:

Convergence study of the maximum intrusion depth for the 2D (

top) and 3D ( bottom) compaction

calibration setups. Filled symbols represent the position of the

filling factor peak of the dust material, whereas empty symbols denote

the position of the minimum filling factor at the gap between glass

bead and dust material. The values are derived from the density

profiles in Fig. 5.

The smoothing length is indicated by the error bars. While the peak

position remains almost constant at

|

| Open with DEXTER | |

Figure 6

shows the results for both cases in 2D (top) and

3D (bottom). The error bars around the minimum values

represent the smoothing length and provide an indication of the maximum

error. The position of the density peak remains almost constant,

converging to ![]() (2D)

and

(2D)

and ![]() (3D),

respectively, at higher resolutions. The position of the

density minimum at low resolutions differs significantly from the

position of the density peak, but converges quickly to the

same intrusion depth at higher resolutions. However, the differences

between the extrema remain well within one smoothing length. This is

because the sphere and dust sample are separated by about one smoothing

length. Comparing 2D and 3D convergence,

the 3D case seems to converge more quickly.

(3D),

respectively, at higher resolutions. The position of the

density minimum at low resolutions differs significantly from the

position of the density peak, but converges quickly to the

same intrusion depth at higher resolutions. However, the differences

between the extrema remain well within one smoothing length. This is

because the sphere and dust sample are separated by about one smoothing

length. Comparing 2D and 3D convergence,

the 3D case seems to converge more quickly.

Because of the findings of this study, we choose a spatial

resolution of ![]() for additional simulations in 2D. In the

3D case,

for additional simulations in 2D. In the

3D case, ![]() is sufficient,

but

is sufficient,

but ![]() is desirable if feasible. After defining suitable values for the

spatial resolution, we now turn to the numerical resolution, which for

the SPH scheme is given by the number of interaction partners

of each single particle. For the investigation of this feature, we

performed a study utilising the 2D compaction calibration

setup with a spatial resolution of

is desirable if feasible. After defining suitable values for the

spatial resolution, we now turn to the numerical resolution, which for

the SPH scheme is given by the number of interaction partners

of each single particle. For the investigation of this feature, we

performed a study utilising the 2D compaction calibration

setup with a spatial resolution of

![]() and varied the ratio of smoothing length to lattice constant

and varied the ratio of smoothing length to lattice constant

![]() from 2 to 7

in steps of one, where

from 2 to 7

in steps of one, where

![]() determines the initial number

of interaction partners that is smoothed

over. The resulting maximum, average, and minimum

interactions

determines the initial number

of interaction partners that is smoothed

over. The resulting maximum, average, and minimum

interactions

![]() ,

,

![]() ,

and

,

and

![]() and the corresponding

smoothing lengths h

can be found in Table 2.

Additionally, we measured the time

and the corresponding

smoothing lengths h

can be found in Table 2.

Additionally, we measured the time

![]() the computations took,

simulated on 4 cores of a cluster with

Intel Xenon Quad-Core processors (2.66 GHz) for a simulated

time of

the computations took,

simulated on 4 cores of a cluster with

Intel Xenon Quad-Core processors (2.66 GHz) for a simulated

time of ![]() and the number of integration steps

and the number of integration steps

![]() of our adaptive Runge-Kutta

Cash-Karp integrator.

of our adaptive Runge-Kutta

Cash-Karp integrator.

Table 2: Parameters for the convergence study regarding interaction numbers.

![\begin{figure}

\par\includegraphics[angle=-90,width=8cm,clip]{13596f10.ps}

\end{figure}](/articles/aa/full_html/2010/05/aa13596-09/Timg171.png)

|

Figure 7:

Convergence study for the density profile using the 2D setup

and varying the smoothing length h. Through

this variation, the number of interaction partners is varied according

to Table 2.

The glass bead has been removed in this plot. For

|

| Open with DEXTER | |

Comparing the density profiles in Fig. 7

(where the glass bead has been removed), instabilities in the form of

filling factor fluctuations due to insufficient interaction numbers

appear for smoothing lengths

![]() ,

i.e., for

,

i.e., for ![]() .

For

.

For ![]() ,

the density profile has essentially the same shape:

the position and height of the filling factor peak remains

nearly the same and

,

the density profile has essentially the same shape:

the position and height of the filling factor peak remains

nearly the same and ![]() drops

smoothly to

drops

smoothly to

![]() towards the bottom of the dust

sample. Only the sharp edge at the top

of the dust sample is smoothed across a wider range due to the

increased smoothing length.

towards the bottom of the dust

sample. Only the sharp edge at the top

of the dust sample is smoothed across a wider range due to the

increased smoothing length.

Table 2

shows that the number of integration steps

![]() decreases with increasing

interaction numbers. This is because

the elastic waves inside the dust sample are smoothed over a wider

range causing the adaptive integrator to increase the duration of a

time step, since density fluctuations do not have to be resolved as

sharply as when a lower amount of smoothing is applied.

As expected, the computation time

decreases with increasing

interaction numbers. This is because

the elastic waves inside the dust sample are smoothed over a wider

range causing the adaptive integrator to increase the duration of a

time step, since density fluctuations do not have to be resolved as

sharply as when a lower amount of smoothing is applied.

As expected, the computation time

![]() generally increases with the

increasing number of interactions. There

are two exceptions:

generally increases with the

increasing number of interactions. There

are two exceptions: ![]() and

and ![]() .

Here, the decrease in

.

Here, the decrease in

![]() overcompensates for the

increase in the interactions leading to a

decrease in

overcompensates for the

increase in the interactions leading to a

decrease in

![]() .

Hence, a ratio

.

Hence, a ratio

![]() yields

the necessary accuracy and an acceptable amount of computation time.

This study also justifies the choice of

yields

the necessary accuracy and an acceptable amount of computation time.

This study also justifies the choice of

![]() in Güttler et al. (2009)

and we use this ratio throughout this paper.

in Güttler et al. (2009)

and we use this ratio throughout this paper.

According to these findings, for 3D simulations an

average interaction number of theoretically

![]() would be needed to achieve the same numerical resolution. However,

similar simulations are infeasible and our choice of

would be needed to achieve the same numerical resolution. However,

similar simulations are infeasible and our choice of

![]() in 3D is equivalent to

in 3D is equivalent to

![]() in 2D, which should provide sufficient and reliable accuracy.

in 2D, which should provide sufficient and reliable accuracy.

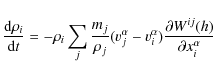

4.3 Geometrical difference - 2D and 3D setups

As one can easily see in Fig. 6,

2D and 3D simulations have significantly different

convergence values for the intrusion depth. This deviation is caused by

the geometrical difference of the 2D and 3D setup.

The 2D setup (glass circle impacts into dust

semicircle) represents a slice through a glass cylinder and a

semi-cylindrical dust sample, which

implies an infinite expansion into the third spatial direction.

In contrast the 3D setup represents a real sphere

dropping into a ``bowl'' of dust. The relation for the

intrusion depth found by Güttler

et al. (2009) (see Sect. 3)

contains a geometrical dependence

![]() ,

where D is the intrusion depth, m is

the mass of the impacting glass bead, v is

its impact velocity, A is its

cross-section, and

,

where D is the intrusion depth, m is

the mass of the impacting glass bead, v is

its impact velocity, A is its

cross-section, and

![]() is the mass per unit length. Güttler

et al. (2009) applied this relation to determine a

rough correction factor between 2D and 3D simulation

setups:

is the mass per unit length. Güttler

et al. (2009) applied this relation to determine a

rough correction factor between 2D and 3D simulation

setups:

Hence, the 2D intrusion depth has to be corrected by a factor of

![\begin{figure}

\par\includegraphics[angle=-90,width=7.8cm,clip]{13596f11.ps}

\end{figure}](/articles/aa/full_html/2010/05/aa13596-09/Timg188.png)

|

Figure 8: Verification of the 2D-3D correction factor. Filled symbols denote the position of the filling factor peak of the dust material in Fig. 5. Triangles represent 3D and squares 2D values. The conversion from 2D to 3D intrusion depth utilising the correction factor from Eqs. (26) and (23) due to the geometrical difference is indicated by the line without symbols. The 3D values are in very good agreement with the very rough theoretical prediction. They lie well within the errors. |

| Open with DEXTER | |

4.4 Artificial viscosity

Since artificial viscosity plays an eminent role in the stability of

SPH simulations, we investigate its influence on the outcome

of our compaction calibration setup. Only artificial ![]() -viscosity

is applied in our test case, but in a threefold way: (1) it

dampens high oscillation modes of the glass bead caused by the stiff

Murnaghan equation of state (EOS). Thereby it enlarges the time step of

our adaptive integrator and saves computation time.

(2) It is used to provide the dust material with a

basic stability. (3) It separates the areas of Murnaghan EOS

and dust EOS and prevents a so-called ``cannonball instability''. For

all three cases, the influence of

-viscosity

is applied in our test case, but in a threefold way: (1) it

dampens high oscillation modes of the glass bead caused by the stiff

Murnaghan equation of state (EOS). Thereby it enlarges the time step of

our adaptive integrator and saves computation time.

(2) It is used to provide the dust material with a

basic stability. (3) It separates the areas of Murnaghan EOS

and dust EOS and prevents a so-called ``cannonball instability''. For

all three cases, the influence of ![]() -artificial viscosity was also

tested, but its influence on all benchmark parameters was found to be

negligible.

-artificial viscosity was also

tested, but its influence on all benchmark parameters was found to be

negligible.

(1) The choice of the ![]() -viscosity of the glass

bead proved to be unimportant. We choose the canonical value

-viscosity of the glass

bead proved to be unimportant. We choose the canonical value

![]() .

No influence on the physical benchmark parameters was detected

for all

.

No influence on the physical benchmark parameters was detected

for all ![]() values,

except

values,

except ![]() ,

which produces an instability. Values of

,

which produces an instability. Values of

![]() have no significant effect on the damping, and the influence for

have no significant effect on the damping, and the influence for

![]() is not too high, but still observable. Hence, we stick to the canonical

value.

is not too high, but still observable. Hence, we stick to the canonical

value.

(2) Sirono (2004)

applies no artificial viscosity to his porous ice material because of

its spurious dissipative properties. Our findings, shown in

Fig. 9,

qualify this choice in terms of the dust material.

Within our 2D compaction calibration setup (

![]() ,

,

![]() ),

we vary

),

we vary ![]() from 0 to 2 and observe its influence on the density

profile (Fig. 9,

top) and the maximum intrusion represented by the filling factor peak

of the dust material (Fig. 9, bottom).

from 0 to 2 and observe its influence on the density

profile (Fig. 9,

top) and the maximum intrusion represented by the filling factor peak

of the dust material (Fig. 9, bottom).

The position of the filling factor peak ranges from ![]()

![]() with

with

![]() to

to ![]() at

at ![]() .

This clearly demonstrates the dissipative feature of the

.

This clearly demonstrates the dissipative feature of the ![]() -viscosity,

since a lower amount of kinetic energy of the glass bead is transformed

into plastic deformation with higher

-viscosity,

since a lower amount of kinetic energy of the glass bead is transformed

into plastic deformation with higher ![]() .

The residual energy must have been dissipated. However, the

.

The residual energy must have been dissipated. However, the ![]() -viscosity-intrusion

curve seems to saturate at a value of

-viscosity-intrusion

curve seems to saturate at a value of

![]() .

The decrease in the maximum intrusion can also be seen in the

density profile (Fig. 9, top).

While the profile maintains nearly the same shape, the height of the

filling factor peak decreases with increasing

.

The decrease in the maximum intrusion can also be seen in the

density profile (Fig. 9, top).

While the profile maintains nearly the same shape, the height of the

filling factor peak decreases with increasing ![]() .

Hence, an increasing artificial viscosity diminishes the peak

pressure during compaction by means of the compressive strength

relation

.

Hence, an increasing artificial viscosity diminishes the peak

pressure during compaction by means of the compressive strength

relation

![]() ,

which is directly responsible for the height of the filling

factor peak.

,

which is directly responsible for the height of the filling

factor peak.

In contrast to Sirono

(2004), we find that it is necessary to apply a small amount

of ![]() -viscosity

to the dust material. For

-viscosity

to the dust material. For

![]() ,

the results show evidences of an instability, which is also responsible

for a rapid increase in the maximum intrusion. Therefore, we find it

convenient to apply an artificial viscosity with

,

the results show evidences of an instability, which is also responsible

for a rapid increase in the maximum intrusion. Therefore, we find it

convenient to apply an artificial viscosity with

![]() to the dust material, which holds for the previous simulations of this

section as well as the following. The choice of a non-zero

to the dust material, which holds for the previous simulations of this

section as well as the following. The choice of a non-zero ![]() ,

however, is also justified by experimental findings: after

impacting into the dust sample, the glass bead shortly

oscillates because of the elastic properties of the dust. This

oscillation is damped by internal friction, which we model with

artificial viscosity. Therefore, by choosing a

non-zero

,

however, is also justified by experimental findings: after

impacting into the dust sample, the glass bead shortly

oscillates because of the elastic properties of the dust. This

oscillation is damped by internal friction, which we model with

artificial viscosity. Therefore, by choosing a

non-zero ![]() we take into account the dissipative properties that our dust material

naturally has. A quantitative calibration of this parameter,

however, is left to future work.

we take into account the dissipative properties that our dust material

naturally has. A quantitative calibration of this parameter,

however, is left to future work.

(3) During our first simulations with the

2D compaction calibration setup, we observed what is sometimes

described in the literature as ``cannonball instability''. During the

compaction process, when the glass bead intrudes into the dust

material, single particles at the sphere's surface begin to oscillate

between the domains of the Murnaghan EOS and dust EOS. Because of the

significant difference in the ``stiffness'' of these two equations of

state, the particles acquire an enormous amount of kinetic

energy until they move fast enough to generate a pressure on the dust

material that exceeds the compressive strength

![]() .

Eventually they disengage from the sphere's surface like a cannonball

and dig themselves into the dust sample causing a huge amount of

unphysical compaction. We tackle this problem for all

SPH particles with dust EOS, which interact with glass bead

SPH particles, by applying the same amount of

.

Eventually they disengage from the sphere's surface like a cannonball

and dig themselves into the dust sample causing a huge amount of

unphysical compaction. We tackle this problem for all

SPH particles with dust EOS, which interact with glass bead

SPH particles, by applying the same amount of ![]() -viscosity

as for the sphere, i.e.,

-viscosity

as for the sphere, i.e.,

![]() .

In our simulations, this is sufficient to prevent the

``cannonball instability''. The spurious dissipation caused by this

measure is negligible.

.

In our simulations, this is sufficient to prevent the

``cannonball instability''. The spurious dissipation caused by this

measure is negligible.

![\begin{figure}

\par\includegraphics[angle=-90,width=7.7cm,clip]{13596f12.ps}\vspace*{1.5mm}

\includegraphics[angle=-90,width=7.7cm,clip]{13596f13.ps}

\end{figure}](/articles/aa/full_html/2010/05/aa13596-09/Timg201.png)

|

Figure 9:

Density profile ( top) and maximum intrusion (

bottom) for different values of artificial |

| Open with DEXTER | |

5 Calibration

5.1 Compressive strength and compaction properties

We refine and extend a study of the compaction properties of the dust

sample, which was already carried out in a similar, but less detailed

way in Güttler et al.

(2009). There the quantity having the strongest influence on

the compaction was found to be the compressive strength

relation

![]() (Eq. (21)),

which was measured in an omni-directional and static manner.

To adapt this relation to dynamic compression, the mean

pressure

(Eq. (21)),

which was measured in an omni-directional and static manner.

To adapt this relation to dynamic compression, the mean

pressure ![]() and the ``slope'' of the Fermi-shaped curve

and the ``slope'' of the Fermi-shaped curve ![]() can be treated as free parameters. The upper and lower boundaries of

the filling factor

can be treated as free parameters. The upper and lower boundaries of

the filling factor ![]() and

and ![]() ,

respectively, remain constant even in the dynamic case. Güttler et al. (2009)

found that by lowering

,

respectively, remain constant even in the dynamic case. Güttler et al. (2009)

found that by lowering ![]() ,

most of the features of the compaction calibration setup can

be reproduced in a very satisfactory manner.

As a result, the ratio of the filling factor to

compressive strength curve (see also Fig. 2 in Güttler et al. 2009)

is shifted towards lower pressures and the yield pressure for

compression is lowered. Using only 2D simulations and a rough

parameter grid, Güttler

et al. (2009) fix

,

most of the features of the compaction calibration setup can

be reproduced in a very satisfactory manner.

As a result, the ratio of the filling factor to

compressive strength curve (see also Fig. 2 in Güttler et al. 2009)

is shifted towards lower pressures and the yield pressure for

compression is lowered. Using only 2D simulations and a rough

parameter grid, Güttler

et al. (2009) fix

![]() .

The ``slope''

.

The ``slope'' ![]() has not been considered.

In this work, we consider

has not been considered.

In this work, we consider ![]() and we perform more accurate parameter studies for

and we perform more accurate parameter studies for ![]() .

From the latter, we predict a reasonable choice for

.

From the latter, we predict a reasonable choice for ![]() ,

which represents the basis of a 3D simulation of the

compaction calibration setup. The results of this simulation are later

compared to results from the laboratory. In this comparison,

we use the same features as Güttler

et al. (2009).

,

which represents the basis of a 3D simulation of the

compaction calibration setup. The results of this simulation are later

compared to results from the laboratory. In this comparison,

we use the same features as Güttler

et al. (2009).

5.1.1 Fixing free parameters

Since no empirical data are available for ![]() in the dynamical compressive strength curve, we perform a parameter

study to determine a suitable choice for this important quantity. For

this study, we use the 2D compaction calibration setup and

vary

in the dynamical compressive strength curve, we perform a parameter

study to determine a suitable choice for this important quantity. For